Lightning Arctic – In situ TEM Solution with Cooling/Heating and Biasing

In situ

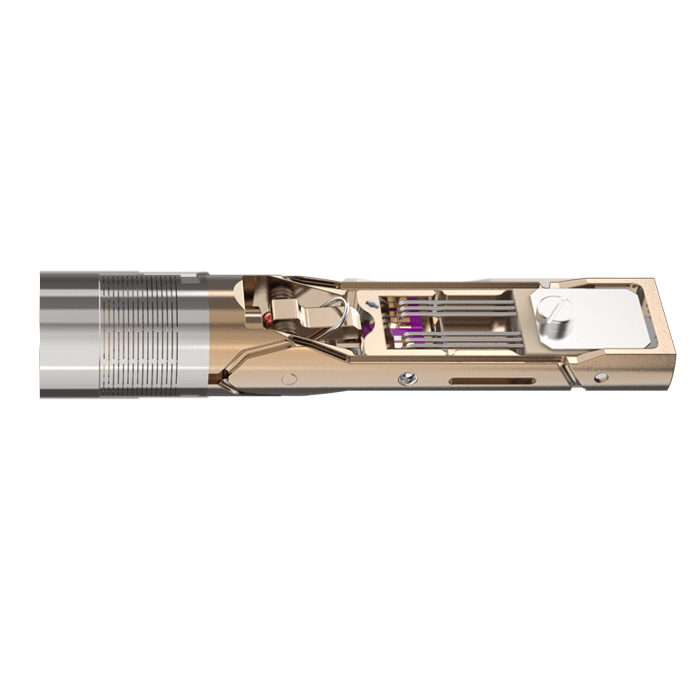

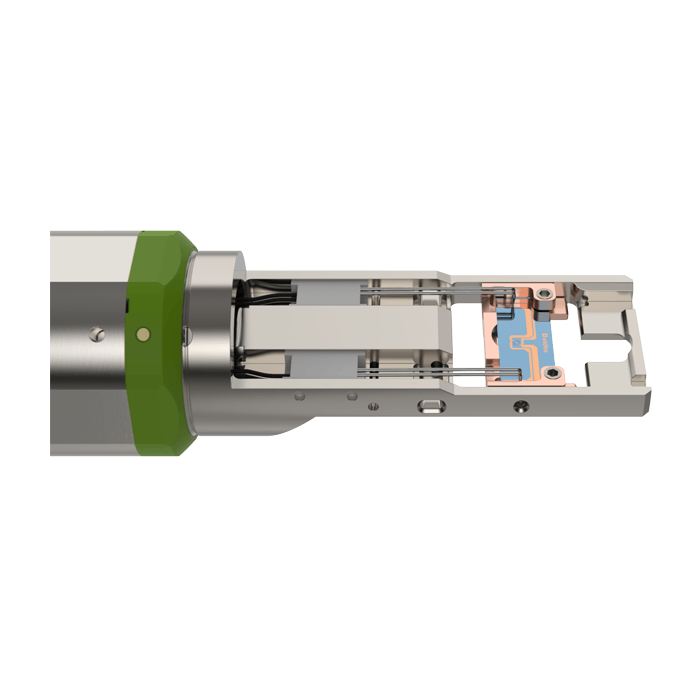

In situ TEM Heating Platform

In situ Heating; Real-time imaging of thermal dynamics inside TEM

Experiment: Thermal degradation of perovskite solar cell

Behavior at the macroscale is strongly linked to atomic arrangement and its transformation. In this example Ru nanoparticles supported on silica are heated to 1300 °C using a DENSsolutions Wildfire system. At that temperatures, the SiO2 sphere evaporates and the Ru nanoparticles become very mobile. The emphasized nanoparticle changes from round to square. This shape change can be studied in detail, due to technology behind DENSsolutions heating systems which ensures high sample stability, sub-Å resolution and therefore enables deeper understanding of the processes involved,

Courtesy of Gatan. Acquired with Wildfire D6 (now H+ DT) and Gatan OneView IS camera on a Thermo Fisher Scientific (FEI) Tecnai TF20

Chemical analysis while heating is extremely important to understand the dynamics of temperature-induced transformations High quality EDS analysis at elevated temperatures is challenging due to the intense generation of infrared radiation during heating which disturbs the X-Ray spectral acquisition. DENSsolutions provides the technology and the experimental evidence that in situ EDS at elevated temperatures is reliable and robust technique across a large temperature range. For the first time it was shown that EDS analysis is possible even at 1000 °C.

Acquired on a Wildfire S3. Maps courtesy of Bruker