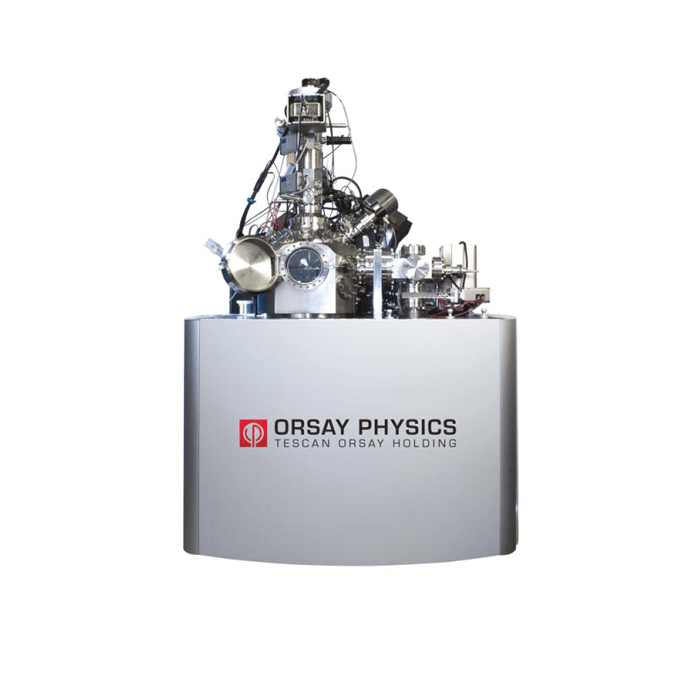

UHV FIB-SEM NanoSpace

AFM/SPM/SNOMCLEDSElectron MicroscopyFabricationFIBSEMWDS

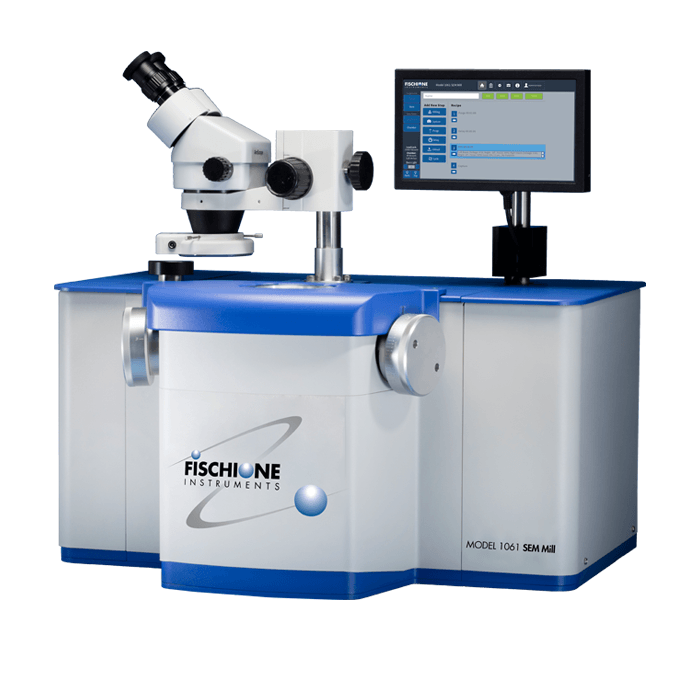

A state-of-the-art ion milling and polishing system.

Table top precision preparation for producing high quality SEM samples for a wide variety of applications

A tool for creating pristine cross-section samples ready for ion milling in the SEM Mill. The station enables precise positioning of the area of interest and can be used with a wide variety of materials, including semiconductor devices, multilayers, ceramics, and hard/brittle materials.

Although milling at low angles with low ion beam energies reduces sample heating, temperature-sensitive samples may require further cooling. The SEM Mill’s liquid nitrogen system features a dewar located within the enclosure that is fully integrated and interlocked effectively eliminating heat-induced artifacts

The ion milling process can be monitored in situ in the milling position when using either the optional stereo or the high-magnification microscope. The stereo microscope (7 to 45 X) enhances sample viewing and with its long working distance allows the sample to be observed in situ while milling. The 525 X or 1,960 X high magnification microscope coupled to a CMOS camera and video monitor to view samples and capture images in situ during milling. This system is ideal for preparing site-specific samples.

An optional vacuum capsule allows you to transfer the sample to the SEM under vacuum or in an inert gas.