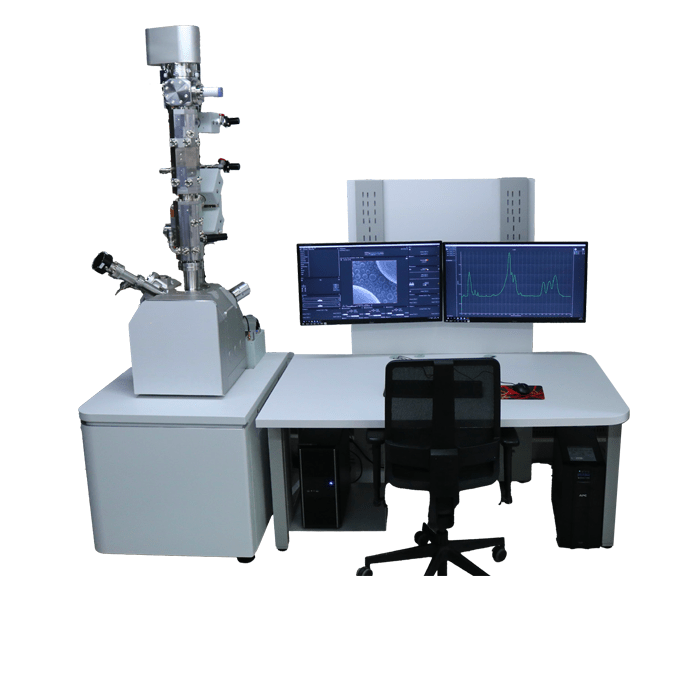

QuiiN - Versatile Ion Implantation System

Fabrication

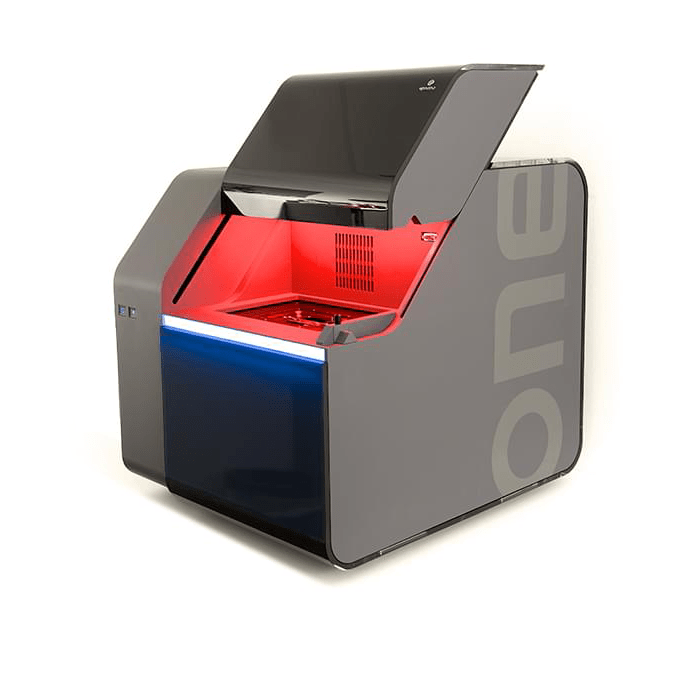

The fastest high-resolution 3D printer on the market

The NanoOne dispels the myth that 2 photon polymerisation bioprinting is slow.

The NanoOne closes the gap between conventional 2PP (2 Photon Polymerisation) printing and microstereolithography. It is the first commercial system that is able to produce components in the centimetre range (up to 42mm) with structural details in the range of 170nm at extraordinary speed.

The NanoOne is suited to applications including:

Run time 2:28 min

This short video demonstrates the main features and capabilities of the NanoOne 2PP printer. Take note of the speed and precision.

Here are some examples of the capabilities of the NanoOne 3D printer that demonstrate the size range of the parts that can be produced and the differing levels of geometric complexity.

Check out this real time demonstration of the NanoOne printing 121 structures each 4 µm x 4µm x 12 µm in only 30 seconds.

Using a novel 3-step process, you can print fused silica components in the cm size range with micon scale features with the NanoOne. Featured here: