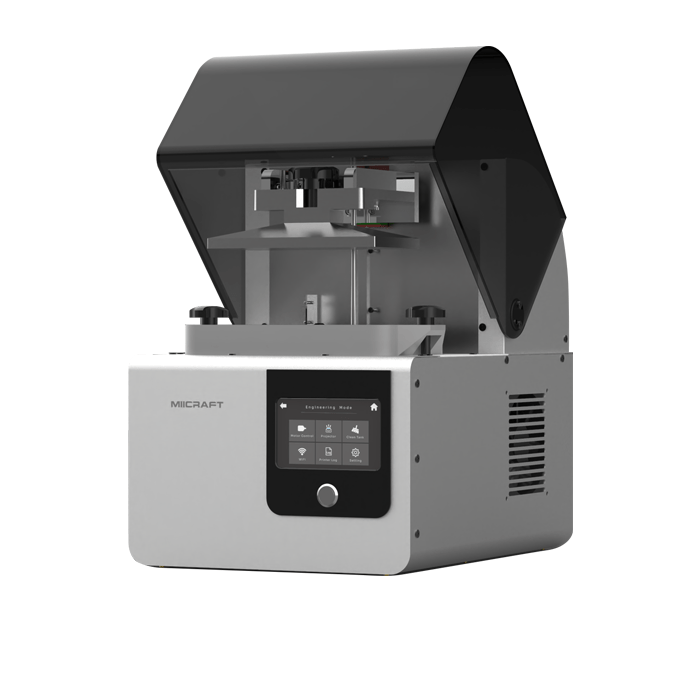

Alpha – Budget-Friendly 3D Printer

Additive Manufacturing

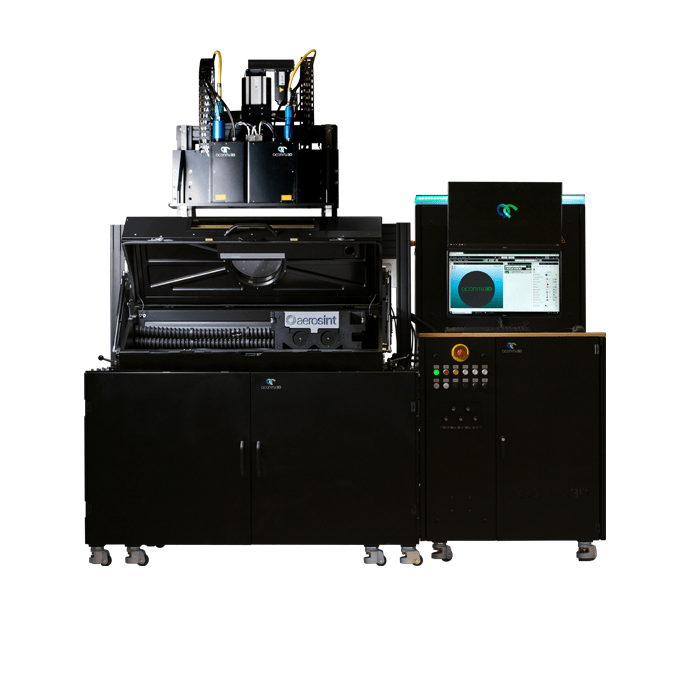

LPBF system with industrial-scale capabilities

Suited to efficient industrial LPBF applications

The AconityMIDI+ has been designed with efficient production suitable for industrial scale applications. Utilising the exchangeable process chamber, enables you to prepare the next processing run while the system is still running minimising transition times.

You can tailor your AconityMIDI+ for maximum material flexibility and quality assurance with options such as high temperature preheating of up to 1000 °C and Aconity3D‘s all new process monitoring systems are available. For maximum productivity, the AconityMIDI+ is also available with up to 4 Lasers in the QUATTRO-Laser configuration.

Common to all Aconity3D systems, the AconityMIDI+ is equipped with the web-based control software AconitySTUDIO, allowing for remote access to all relevant process parameters and machine components.

Aconity3D also offer their revolutionary Multi-Material powder depositioning system. This enables you to fabricate components using three alloys in the same component.

Run time – 1:40 min

Demonstration of the multi-material printing capability of the AconityMIDI+.