Alpha – Budget-Friendly 3D Printer

Additive Manufacturing

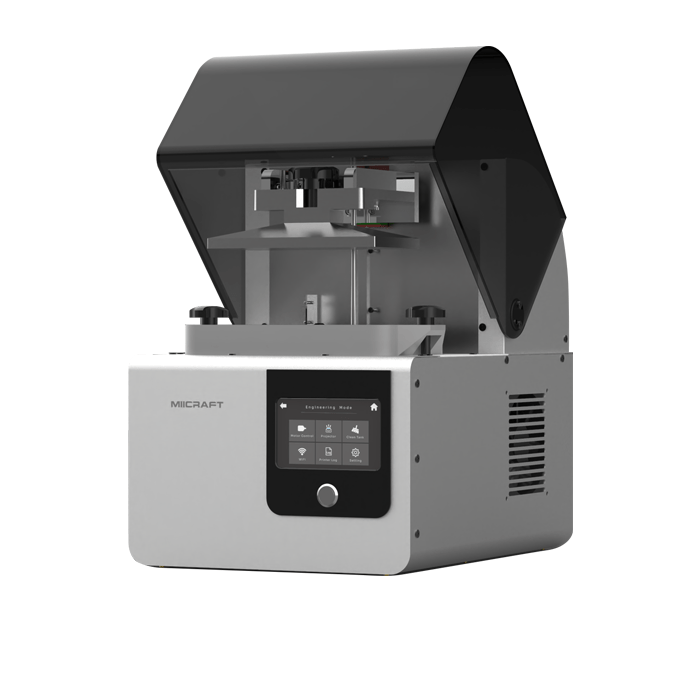

Compact high-vacuum furnace

Ideal for metal 3D printing post-processing and other heat treatment processes requiring controlled atmospheres

Post heat treatments are often required for 3D printed metal components. Distortion as result of the 3D printing post-processing heat treatment is the enemy. The inFurner vacuum furnace has been specifically designed to prevent distortion in pots-processed 3D printed parts.

inFurner is also suitable for any other application where a vacuum furnace is required, and parts require heat treatment under controlled atmospheres from research to industry.