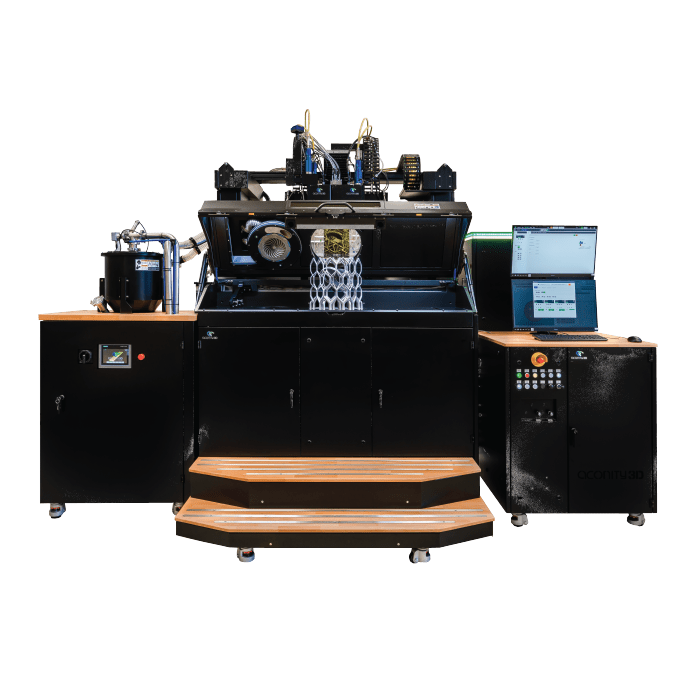

AconityTWO

Additive Manufacturing

Automated support removal system

safeEtch is an innovative metal support removal instrument for removing supports from metal prints quickly and easily.

safeEtch uses a patented chemical solution to dissolve a uniform layer of material over the entire 3D printed part. The thickness of the layer is predefined by process parameters and taken into account during part design. Consequently, supporting structures are dissolved with additional surface treatment. Ultrasonic agitation ensures solution flows into every internal feature, thus treating the whole part uniformly removing supports effectively.

safeETCH can be configured with different working chamber volumes to suit your jobs and is currently compatible with: