By Dr. Hesam Shahali1, Dr. Cameron Chai2, Dr. Kamran Khajehpour2 and Prof. Prasad KDV Yarlagadda OAM1

From spider’s silk which exhibits strength 3 time greater than aramid fibres and 5 times stronger than steel, to human bone that simultaneously offers strength and toughness, to geckos feet which allows them to scamper upside down across ceilings, through to the ability of animals to colour change, mother nature has been the inspiration for many materials research projects. It was again mother nature who provided the impetus for Hesam Shahali under the supervision of Prof. Prasad KDV Yarlagadda OAM to follow the lead of the cicada at QUT and the Central Analytical Research Facility (CARF).

Nanostructured Cicada Wings

Cicada wings have been shown to exhibit bactericidal and cytocompatible properties on account of their nanoarchitecture. These properties are as a result of the nanopillars and the ability to mimic these structures could be beneficial in fighting infections associated with biomedical implants. Key to the success of these structures are parameters including:

- Base diameter – 90 to 210nm

- Top diameter – 13 to 50nm

- Aspect ratio ~ 2.16 to 2.35

- Nanopillar density ~ 10 to 43 N/µm2

Nanofabrication Techniques

Their criteria for a suitable nanofabrication process was to find a high resolution (sub 100nm) fabrication technique that can work with metals at a relatively low cost. After reviewing processes such as UV Lithography, EBISA (Electron Beam Induced Surface Activation), FIB (Focused Ion Beam) and EIBD (Electron Beam Induced Deposition), the technique that offered the best combination was EBL or Electron Beam Lithography. EBL is a flexible and reliable technique for nanofabrication and has a successful track record in the areas of high-resolution fabrication of semiconductors and sensors.

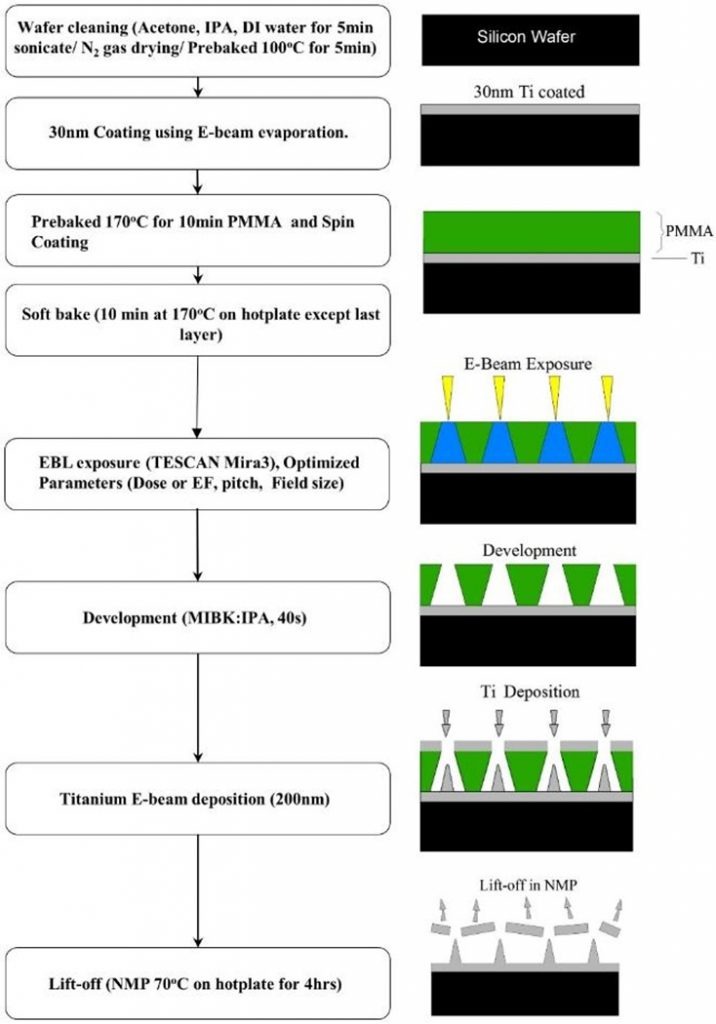

Fabricating Nanostructures on Titanium Using EBL

EBL does have the disadvantage that it cannot be used to directly mill into metals due to the low mass of the electrons. This is a problem as titanium (and certain alloys thereof) is the material of choice for orthopaedic implants due to its suitable mechanical properties and biocompatibility. As a result, patterns must be transferred to the material using polymer-based E-beam resists. PMMA (polymethylmethacrylate) is generally the optimal material for this application when positive tone electron beam lithography is required to fabricate closely spaced features, generally less than 100nm.

In their research they used a TESCAN EBL package based on the MIRA FEG-SEM. It comprised an ultra-fast beam blanker and a comprehensive patterning software package called TESCAN DrawBeam that is fully integrated for seamless operation.

EBL Fabrication Parameters

In terms of the EBL, there are a number of parameters that also need to be optimised including:

- Exposure energy (kV)

- Dose (µC/cm2)

- Pattern generator factors

- Resolution mode

Novel EBL Nanofabrication Approach

The novelty of this study lies in the systematic approach used to simulate and fabricate closely spaced nanopillars inspired by cicadas without etching that will provide antibacterial properties, making them suitable for implants.

Optimising the EBL Process

The Monte Carlo model was used to simulate the E-beam scattering on the resist to optimise the energy of the beam and the pattern design on different resist thicknesses. This approach optimised the EBL processing parameters, in particular Exposure Factor (EF, sometimes called dose) as well as pattern design, working distance, spot size, beam intensity and write field size prior to actual EBL processing, resulting in reduced experimental time and effort.

Monte Carlo simulations showed that for PMMA mask thicknesses >500nm, 30kV was the optimal exposure energy, exposing the overall thickness of PMMA and the circle pattern used produced the optimum simulation result relating to better lift-off and higher fabrication resolution.

The optimised process for depositing the titanium nanopillars consisted of depositing 3 layers of PMMA 495 A4 and one layer of PMMA 950 A2 over a write field of 25 x 25µm followed by coating with 250nm of titanium.

Determining the Antibacterial Effectiveness

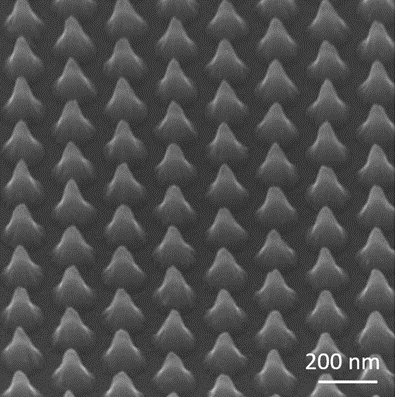

In terms of antibacterial effectiveness, the authors trialed a number of configurations and found that high density and smaller centre-to-centre distancing with a sharper nanopillar configuration has the best killing performance. Table 1 compares the EBL fabricated nanopillars to the those of the Palapsalta Eyrei (PE) cicada.

| Cicada Wing | EBL Nanopillars | |

|---|---|---|

| Spike diameter (nm) | 60.2 | 12.6 |

| Base diameter (nm) | 123.2 | 95.5 |

| Spike height (nm) | 211.2 | 115.6 |

| Centre to centre distance (nm) | 155.9 | 165.8 |

| Aspect ratio | 2.3 | 2.15 |

| Spike density (N/µm2) | 40 | 43 |

Compared to the biological cicada nanopillar configuration, the EBL fabricated titanium nanopillars have a higher density and sharper tips. This should have an enhanced bactericidal effect against a range of bacteria.

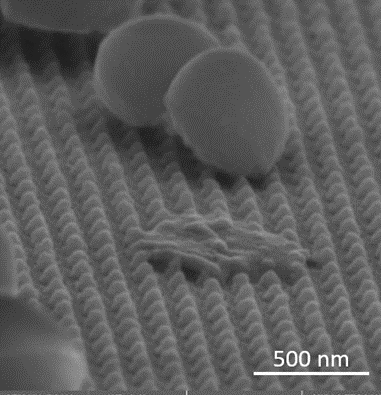

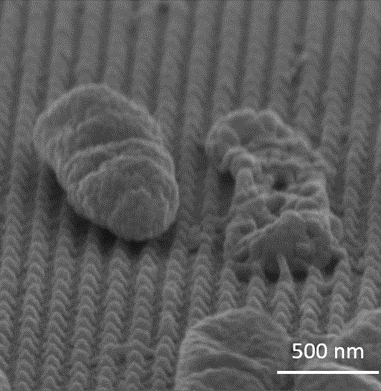

When tested with P. aeruginosa and S. aureus cells, the bio-inspired titanium nanopillars indeed disrupted the cell morphology of both types of bacteria, especially in relation to the titanium control.

Figure 4. Figure 4. SEM image of S.aureus (left) and P.aeruginosa (right) interaction with fabricated nanopillars in tilt angle 45 degree based on design Ø70 nm, centre to centre distance of 160 nm and final geometry with base diameter 94.4 ± 6 nm, spike diameter 12.6 ± 2 nm, centre to centre distance 165.8 ± 5.6 nm and aspect ratio 2.16.

Summary

This study illustrates that it is possible to take inspiration from nature and that the authors have successfully fabricated titanium nanostructures using EBL using a TESCAN SEM. Using a novel process incorporating computer simulation to refine the workflow before any physical processing had taken place, they were able to accelerate the experimental process. The resultant EBL fabricated nanopillars were also shown to exhibit the desired antibacterial properties that have potential application to enhance the biocompatibility of orthopaedic implants.

This article has been adapted from “A systematic approach towards biomimicry of nanopatterned cicada wings on titanium using electron beam lithography”. More information about this research can be found at “Multi-biofunctional properties of three species of cicada wings and biomimetic fabrication of nanopatterned titanium pillars” and Hesam’s PhD thesis “Assessment of the bactericidal effect of biomimicked nanopillars of cicada wings on titanium implants”.

Author Affiliations

- Centre for Biomedical Technologies, Science and Engineering Faculty, Queensland University of Technology, Brisbane, Queensland 4000, Australia

- AXT PTY LTD, Warriewood, NSW, 2120, Australia