LabTIE Freeze-dried OP50

Sample Preparation

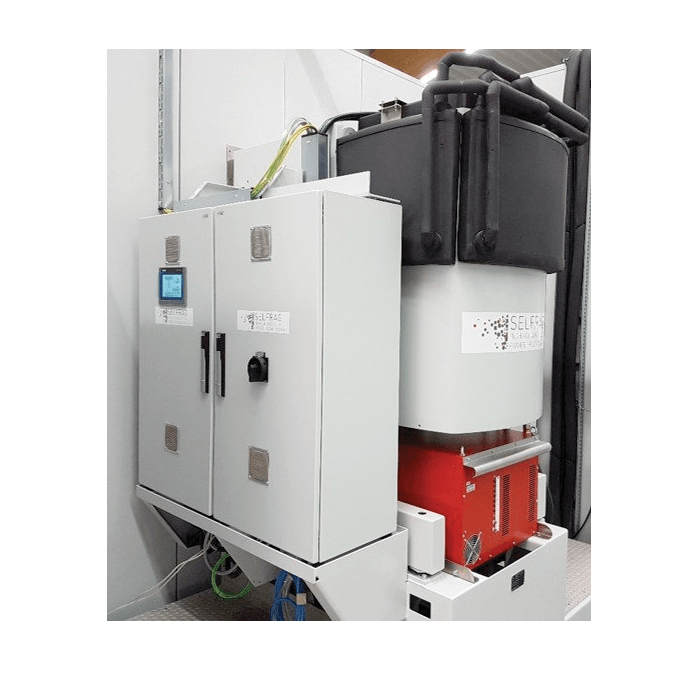

Crushing of high purity products with less than parts per trillion levels of introduced contamination

Contactless crushing of high purity products with less than parts per trillion levels of introduced contamination

The SELFRAG Rod Crusher gives virtually zero contamination and has seen leading silicon manufacturers worldwide choose the SelFrag Rod Crusher to increase both production efficiency and product quality.

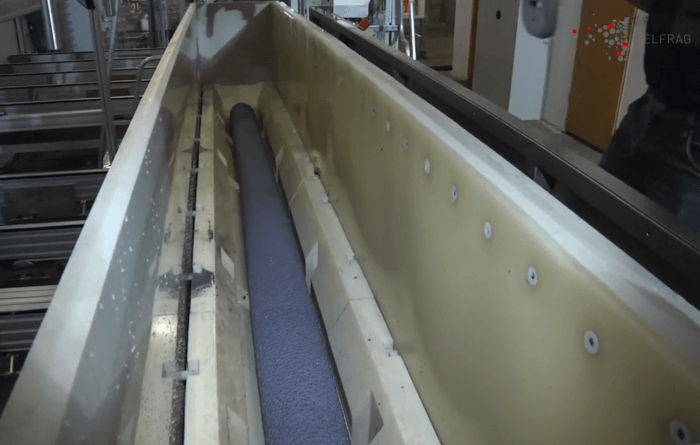

High Purity Silicon Rods are loaded into the reaction vessel

The crush size distribution is programed

The resulting product is dried and bagged