Radiographic testing is a form of non-destructive testing (NDT). Its application and methodology in materials testing is very similar to radiography used in medicine where it is used to identify such things as broken bones.

The technique relies on the differences in transmission and absorption characteristic of various features. In materials testing, it is used to reveal defects including cracks, flaws, pores, voids, wall thickness variations and even discontinuities in electric circuits.

It requires a radiographic generator, often referred to as a tube head, which produces x-rays. To produce meaningful results, the radiographic generator must be powerful enough to produce x-rays that will pass through the specimen.

The x-rays themselves are produced by an x-ray tube. They do this by using electrons from a (negatively charged) cathode filament and accelerating them using high voltage towards a (positively charged) anode. When the electron beam strikes the anode, electrons in the inner shells are excited. As the electrons fall back to their equilibrium state, x-rays are emitted. These x-rays are then directed towards the specimen. The x-rays that pass through the specimen can then be detected using x-ray film, linear detector or digital flat panel. AXT supplies radiographic generator sets from Rigaku and Yxlon.

Pulsed Power vs Constant Potential

Radiographic generators fall into two categories based on the type of output they generate. They can be either:

- Pulsed Power – X-rays are produced in an intermittent fashion. Rigaku produce a range of pulsed power x-ray sources.

- Constant Potential (CP) – These systems produce a constant beam of x-rays. Yxlon and Rigaku produce CP x-ray sources.

Despite the different ways the x-rays are delivered, both types of radiographic generators produce the same results, as x-ray film and digital detectors work on total (or cumulative) intensity received. Cp systems will however, reduce overall exposure times, meaning you can image more samples in a shift.

Directional vs Panoramic

Radiographic generators emit x-rays in one of two modes:

- Directional – X-rays are produced in a cone-shaped configuration. This mode is suited to examination of specific features and smaller components e.g. weld testing and crack detection in aircraft components. Both Rigaku and Yxlon manufacture directional radiographic generators.

- Panoramic – The radiographic generator radiates x-ray in a disk-like configuration. This mode is suited to pipeline inspection. Only Yxlon produce panoramic radiographic generators. These can be integrated with crawlers to examine long lengths of pipeline.

Portable vs Mobile

AXT can supply portable radiographic generators from Rigaku and Yxlon. These are great when there is sufficient space to manoeuvre the systems into place. Where space is an issue, Yxlon have mobile solutions with the generators being mounted on a trolley. These are ideal for applications such as nuclear power and petrochemical plants.

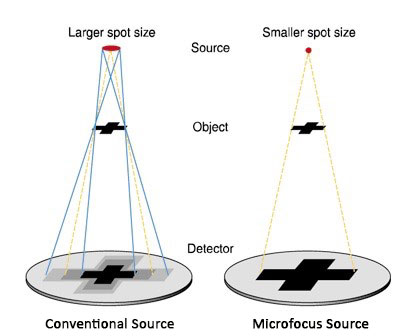

Fine Focus

Fine focus systems offer higher resolution imaging capabilities. For more information about how these systems work click here.

Radiographic Generator Sets for Hire

AXT now have a fleet of constant potential x-ray generators available for hire from Rigaku and Yxlon. For more details, click here.