PµSL 3D Printing Technology and Applications

2μm PμSL Based 3D Printing and its Applications in Microfluidics and Microneedles

The trend towards miniaturisation is occurring in more and more types of products and technologies, especially medical devices, flexible electronics, communication systems, robotics, metamaterials, etc. Traditional manufacturing technologies face greater challenges in producing parts that are smaller in size but more complex in structure. For example, it is costly and time-consuming to build a mold for micro-injection molding or to complete the initial programming for CNC machining. Lithography technologies are mold-free, but require complex manual operations, resulting in very low productivity.

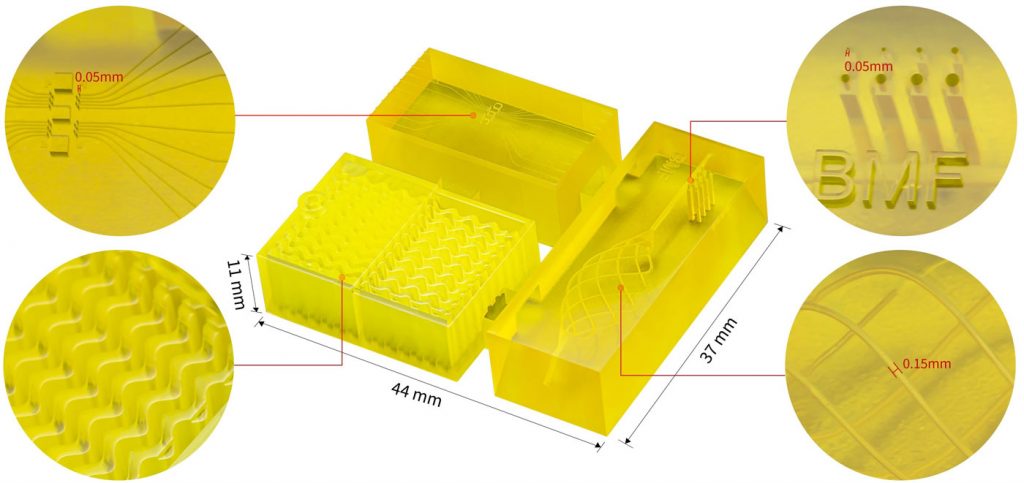

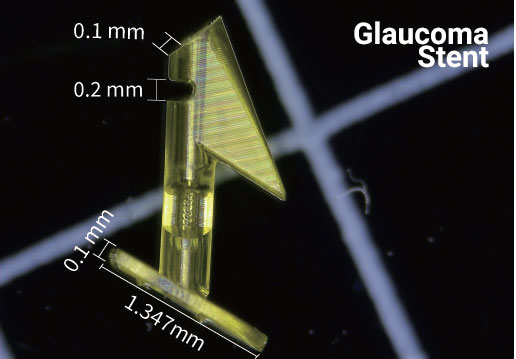

To address the challenge of microfabrication, projection micro stereolithography (PµSL) technology, with its breakthrough resolution of 2µm/10µm, has been increasingly applied in microfluidics and microneedles. Through continuous development, PµSL has enabled multi-scale fabrication from 10μm to 100mm, high aspect ratio, high production efficiency, excellent biocompatibility, good performance for PDMS molding, and microscopic observation.

Presenter – Donald Chen

Donald Chen is a Senior Sales Manager on the Boston Micro Fabrication (BMF)-APAC team with over 4 years of experience in microfabrication. Having worked with innovative biomedical companies and research groups for many years, he has a unique insight into microfluidic and microneedle manufacturing.

Novel Movable Typing for Personalised Vein-Chips in Large Scale: Recapitulate Patient-Specific Virchow’s Triad and Its Contribution to Cerebral Venous Sinus Thrombosis

Cerebral venous sinus thrombosis (CVST) is receiving growing attention due to its association with stroke and COVID-19 vaccine-induced immune thrombotic thrombocytopenia. CVST remains poorly understood due to highly heterogenous Virchow’s triad of altered blood flow, endothelial dysfunction and hypercoagulability, which vary from patient to patient. Current diagnostic and surveillance strategies fail to capture these thrombotic determinants in a patient-specific manner.

To address this, we developed a Vein-Chip platform that integrates the CVST vascular anatomy from magnetic resonance venography and the associated hemodynamic flow profile using the “Chinese Movable Type” like soft stereolithography technique. The Vein-Chip recapitulates CVST Virchow’s triad, enabling systematic characterisation of venous thrombogenesis with respect to fibrin formation and platelet aggregation. In contrast to the arterial settings, platelets universally adhere across the entire CVS Vein-Chip, independent of stenotic geometry and flow disturbance. Fibrin propagates along the flow direction but exclusively deposits on the inner vessel wall. In the event of inflammatory endothelial injury, fibrin deposition mirrors the outer vessel wall but still not in the lumen. Our Vein-Chip promises future applications for personalised thrombotic assessment and monitoring. It is inexpensive, rapid, and allows for large-scale biomanufacturing for clinical use.

Presenter – Charles Zhao

Yunduo (Charles) Zhao is the CEO of a startup company and PhD student funded by NHMRC and Heart Foundation scholarships (CIA). He developed a microfluidic-based blood clot testing tool, a blood vessel modelling framework, a novel cost-efficient PIV system, and a multi-scale haemodynamic simulation platform during his research. In conjunction with his supervisor A/Prof Arnold Ju, they pioneered low-volume microfluidic devices to monitor blood function under cardiovascular and cerebral diseases. Such devices hold great potential to be translated into point-of-care disposable chips with patient-specific vascular geometries that allow scalable manufacturing and reliable preclinical blood clot test.