On-demand webinars

Additive manufacturing is a rapidly growing field. This bottom up manufacturing technology is freeing up engineers from the restrictions of more conventional top down manufacturing processes enabling more complex components to be produced faster and more economically.

One small issue with additive manufacturing is throughput, i.e. it is more suited to producing small quantities, even one-offs, of complex components. As these components have often taken hours to produce, the production process needs to be well understood and the quality of the final component free of defects.

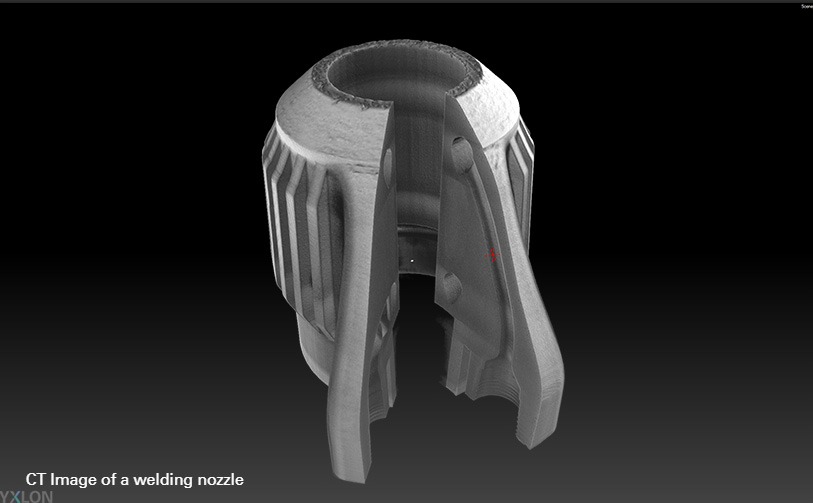

Computed Tomography now comes into play as the ideal partner for additive manufacturing providing full 3D inspection. With its ability to help evaluate and refine the process and to non-destructively perform quality control inspections on finished products to avoid catastrophic premature failures.

In these two on-demand webinars, we present examples of how computed tomography can assist those involved in additive manufacturing.

Computed Tomography – Accelerating Additive Manufacturing Analysis

Computed Tomography (CT) with powerful software is the most superior inspection technique available for AM. They can be used throughout the entire workflow from analysis of powders, to melt pool analyses to inspection of the final part for anomalies such as porosity, cracks, inclusions or remaining powder that must be detected.

In this webinar specific examples will be presented to demonstrate the applicability of the technology and how the powerful software can be used.

4D Computed Tomography in Additive Manufacturing – Extending the Frontier from 3D to 4D

Computed Tomography (CT) is a non-destructive technique used to create highly detailed 3D volumes of intact samples and is widely used for process development, process monitoring, and quality assurance of final parts. At TESCAN, their micro-CT products are well suited to this challenge; providing maximum flexibility and versatility, as well as opening up the possibility to perform 4D studies on samples.

In this webinar we will provide background on the basics of micro-CT, examples of imaging various 3D printed samples, and discuss the future of micro-CT, dynamic CT, where samples are continuously scanned at high rates while undergoing change, either naturally or induced. Watch the webinar to see the possibilities micro-CT brings to the additive manufacturing space!