Microfluidics are devices that process or manipulate miniscule volumes of liquids (sometimes containing cells). It is not uncommon for them to deal with only femtolitres (fL), or a quadrillionth of a litre at a time. They are already used in commercial instruments including bioprinters (link to Fluicell) and lab-on-a-chip devices (link to Physiomimix) and high-performance but cost-effective diagnostic techniques during the COVID-19 pandemic.

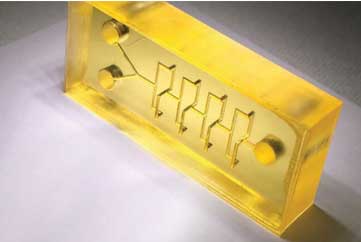

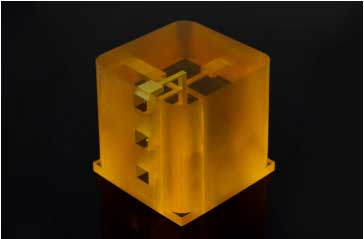

Microfluidic devices often incorporate complex channels that can be extremely difficult to fabricate using traditional techniques, but relatively simple using 3D printing.

Traditional Techniques for Fabricating Microfluidics

Small quantities of microfluidic devices can be produced manually. However, this is a time-consuming, labour-intensive process requiring the cutting of features into layers and then laminating them together.

For larger quantities of microfluidic devices, injection moulding can potentially become an option. In this case, the tooling/moulds can be extremely expensive to produce and can also take many, many hours to fabricate. Once the tooling has been made (and paid for), large volumes of devices can be produced at low cost per piece.

3D Printing Microfluidics

3D printing offers new levels of freedom for those wanting to produce microfluidic devices. Using lithography-based techniques, microfluidic devices can easily be created with channels with diameters under 100µm in diameter, channels that change direction and size, with degrees of complexity only limited by your imagination.

Polymers lend themselves to these processes and are also convenient as they come in a range of options such as high strength, biocompatible, high temperature resistance or chemical resistance. In most cases they are also very cost effective.

3D printing also facilitates rapid prototyping, i.e. you can easily print a prototype, test it and then print another one with further optimised characteristics.

3D Printing Technologies

To produce microfluidic devices with tiny channels that may be directed in any direction, resin printing techniques based on digital light processing (DLP) are used. These essentially involve adding a layer of resin and polymerising it using a flash of light directed via a digitally controlled mask so that only specific areas are built up.

Variations on this technology include:

- Projection Micro Stereolithography (PµSL)

- Two Photon Polymerisation (2PP)

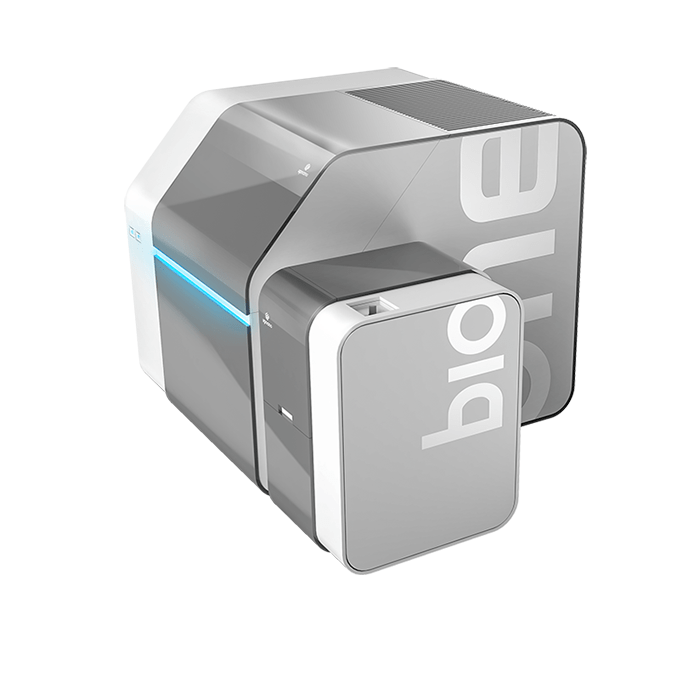

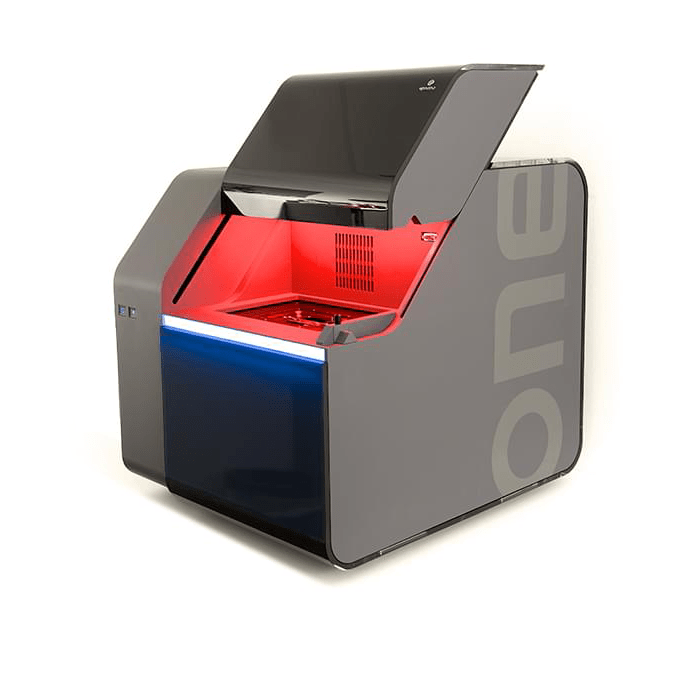

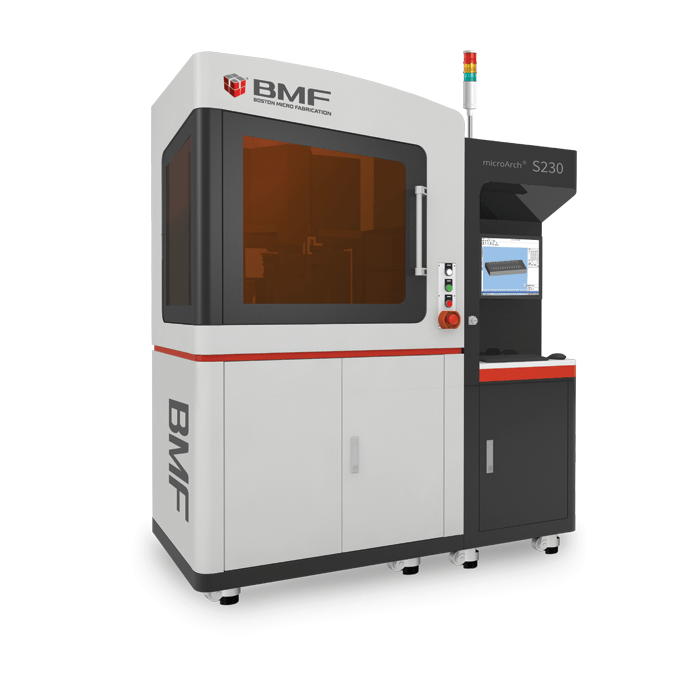

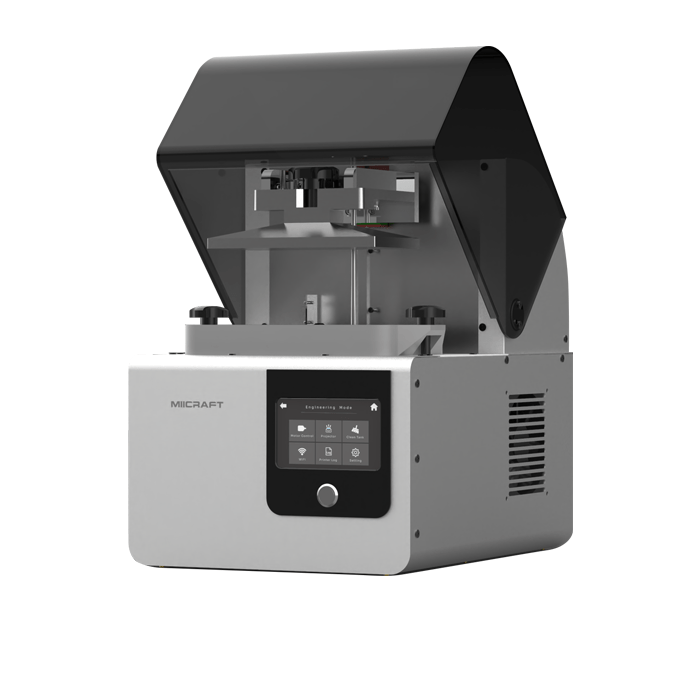

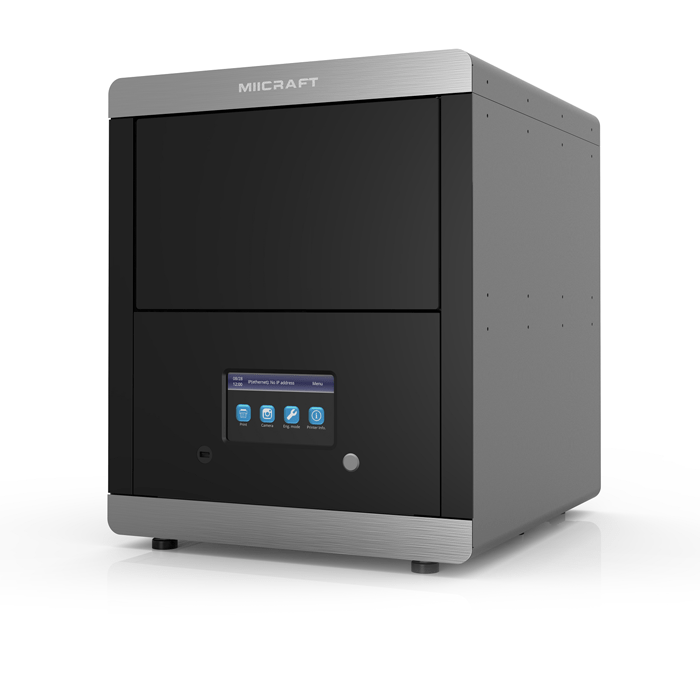

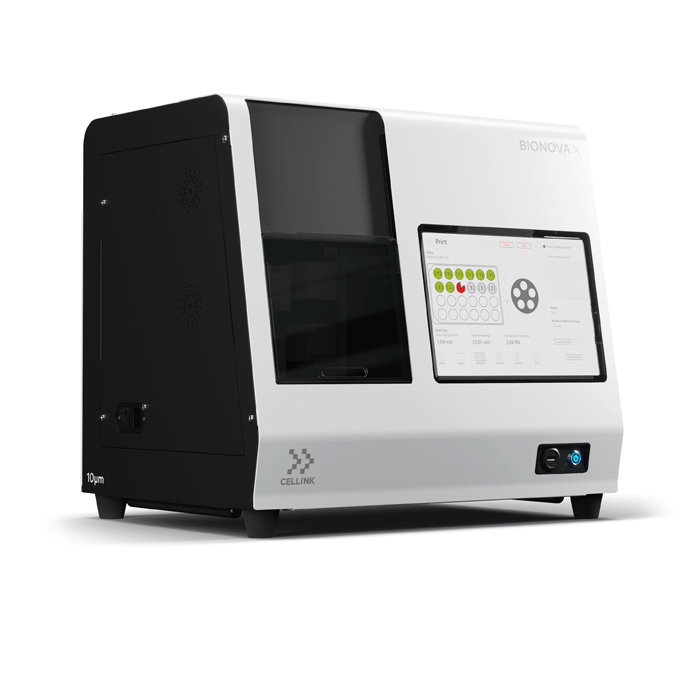

3D Printers Suited to Fabrication of Microfluidic Devices

Applications Using Microfluidic Devices

Microfluidics are used in areas such as:

- DNA and RNA sequencing

- Healthcare

- Biology

- Medicine

- Lab-on-chip devices

- High-throughput screening