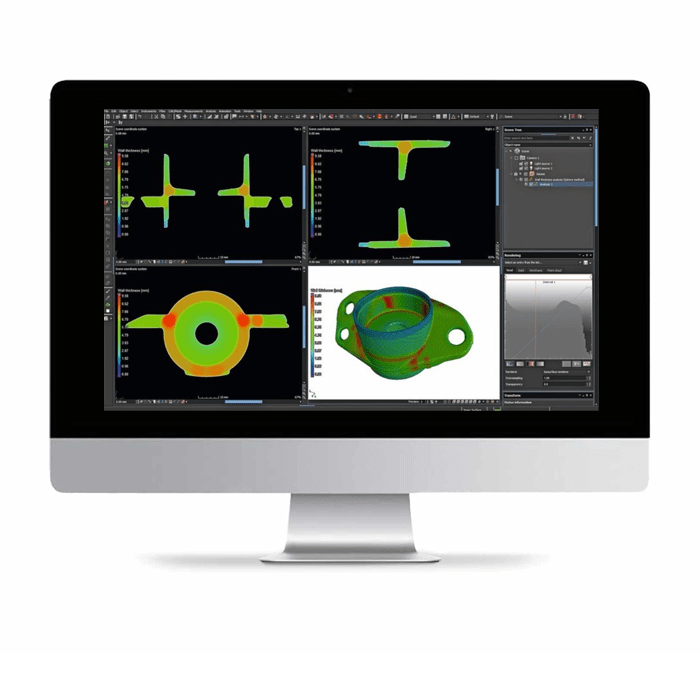

VGSTUDIO MAX

Computed Tomography

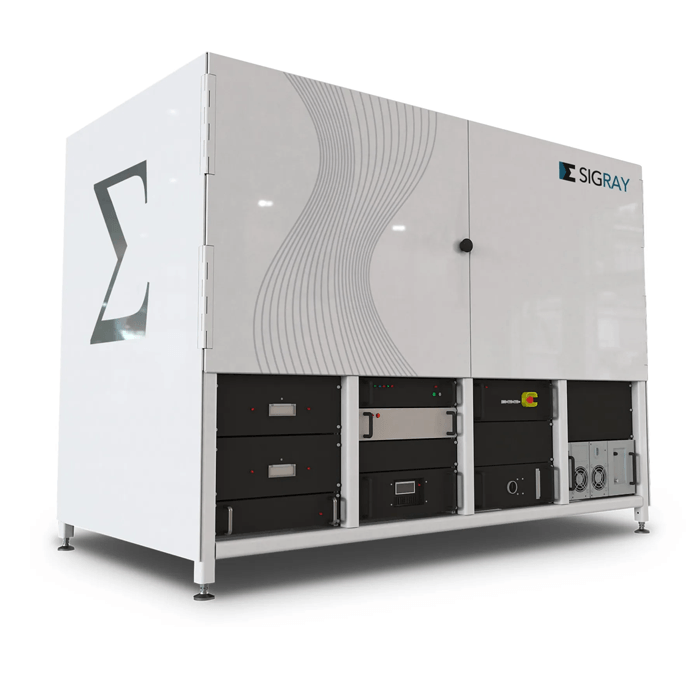

Sigray’s Apex-XCT™ is a revolutionary 3D X-ray computed tomography (XCT) system optimised for flat samples.

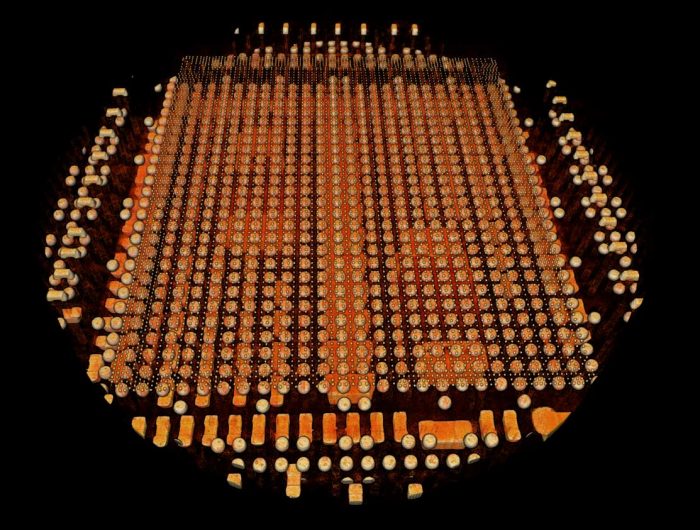

Sigray’s Apex-XCT™ is a revolutionary 3D x-ray computed tomography (XCT) system optimised for flat samples, such as for failure analysis of advanced packages, printed circuit boards (PCBs), cell phones, pouch cell batteries, and wafers. The system achieves submicron spatial resolution within 10 minutes, even for very large flat samples.

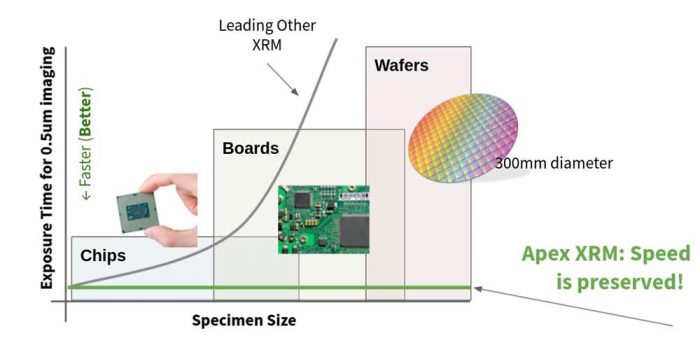

The Apex-XCT was designed to address a well-known problem in 3D x-ray imaging approaches in which the required acquisition time exponentially increases with sample diameter. This makes tomography of large samples such as intact, uncut PCBs and 300mm wafers practically impossible. Apex-XCT uses a breakthrough patent-pending acquisition method in which the source-sample distance is minimized throughout acquisition, thus preserving high speeds that are independent of sample diameter.

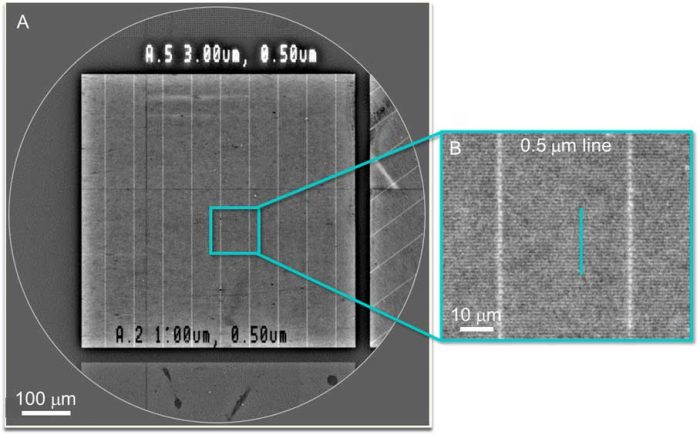

Apex XCT-100 offers spatial resolution on 0.5µm anywhere on your sample and ideal for failure analysis of large flat components e.g. entire packages, wafers and PCBs which could be time consuming or require destructive analysis on other systems.

With the Apex XCT-100 data acquisition time is independent of sample size. The unique geometry of Apex XCT preserves high throughput operation even with increasing sample sizes. This makes it an ideal choice for inspecting printed circuit boards, motherboards and wafers.

Scans of entire boards at high resolution (8 micron voxel) are easily stitched together for reverse engineering applications. The video shows stitched volumes, with each scan taking only 36 minutes.

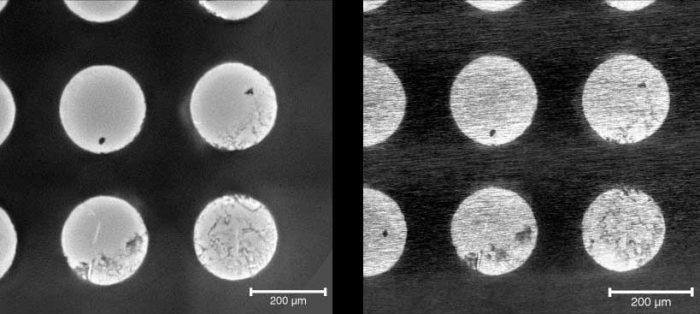

Apex XCT eliminates many of the imaging artefacts that affect operation of conventional 3D X-ray systems, such as beam hardening, streaking/curtaining, photon starvation, and metal artifacts. This image compares the same region imaged with Apex XCT (Left) and a leading Conventional XRM/microCT (Right). As can be seen, the Apex XCT result demonstrates a dramatic increase in image quality while also offering a significantly reduced scan time.

A state-of-the-art 25-watt 30-160 kVp nanofocus sealed tube X-ray source combines highest power and spatial resolution with maintenance-free operation.

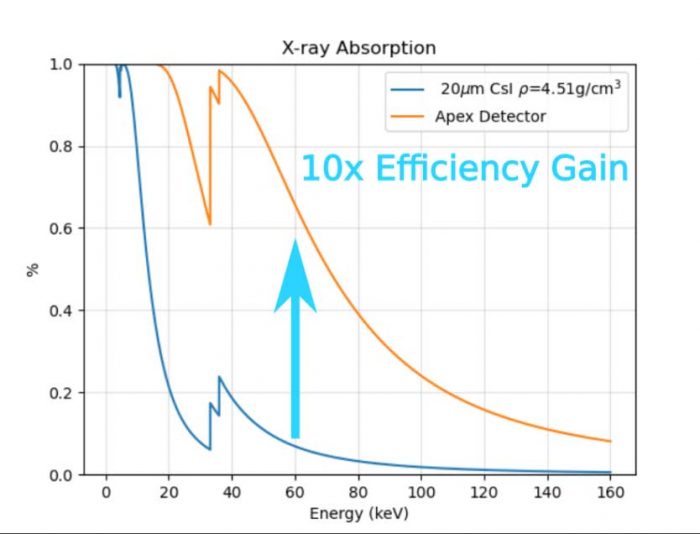

The Apex XCT’s detector has been carefully optimised for high-resolution, high-throughput operation at voltages up to 160 kV. Legacy CT systems rely on thin scintillators for high-magnification imaging, which are highly inefficient at high energies. Apex XCT, by comparison, absorbs a much wider portion of the X-ray spectrum offering massive throughput improvements.