TESCAN TIMA

Automated MineralogyEDSSEM

With our thirst for portable electronics and electric cars, the value of the lithium battery market is expected to surge from from US$30.2 billion in 2017 to US$100.4 billion by 2025 (Statista). As a result, the demand for lithium should rise accordingly with a corresponding need for efficient beneficiation .

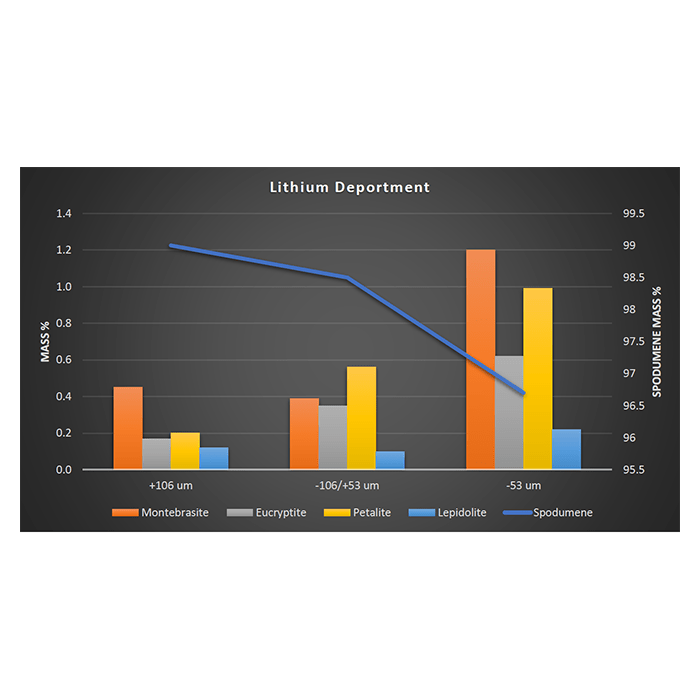

The TESCAN TIMA-X automated mineralogy solution is a system that can be integrated at all stages throughout a lithium plant, for the entire mine life from discovery to recovery. This case study demonstrates how this solution can be used to optimise all stages of the process, from determining which lithium-bearing minerals are present which can help to determine the economic value of your deposit all the way to optimising process flow sheets for grinding, flotation and leaching strategies to maximise yields and recovery, and ultimately economic return.

If you have a lithium plant or any other process metallugy plany for that matter, you can test drive the TESCAN TIMA-X at the Automated Mineralogy Incubator which houses the most advanced system in the southern hemisphere.