Y.XMB Series Mobile X-ray Systems

Radiography

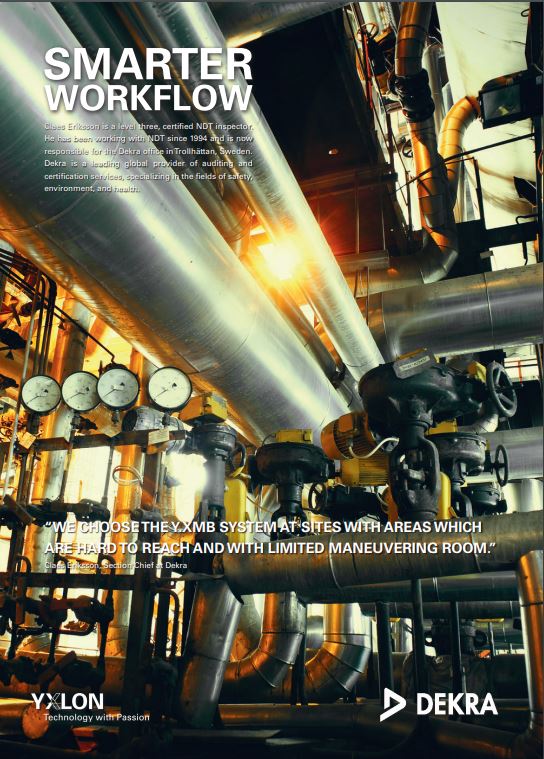

The Swedish branch of Dekra is contracted for many different types of inspection jobs, and for Claes, it’s all about choosing the right tool for the job. The jobs often call for X-ray inspection, in hard to reach and cramped spaces, typically at refineries and power plants.

In such cases, Claes chooses the mobile Y.XMB system from YXLON Copenhagen. Claes explains why: “The Y.XMB 160 with the small 0.4 mm focal spot was originally acquired for inspecting turbines, but we most often use it at refineries and power plants because of its versatility, mobility, and the extremely high resolution the small focal spot provides. It simply gives us the necessary level of detail that we need.”

One of these sites is in Lysekil, Sweden, one of the largest refineries in Scandinavia. “We choose the Y.XMB system at sites with areas which are hard to reach and with limited maneuvering room. The long reach of the Y.XMB and its small tube head makes it ideal for these types of inspection jobs,” Claes elaborates.

The versatility of the Y.XMB system is also a great asset. It supports a wide range of different, high-quality X-ray tubes, produced by COMET Technologies, from directional, panoramic to fan beams, all with different beam shapes and differently sized focal spots. The systems also feature a broad milliamp range from 0-20 mA.

The Y.XMB is ideal when mobility and versatility is essential to get the job done.