TESCAN CLARA

Electron Microscopy

Introduction

Ceramic materials are used in a wide range of applications because of their diverse properties. In general, ceramics are considered as materials with great mechanical properties and high-temperature resistivity. However, ceramic materials also exhibit useful electrical, optical, and biological properties. The properties of ceramics strongly depend on chemical composition, crystallography and porosity. Hence, their applications spread through different fields ranging from grinding materials, bearings and disk brakes to coatings on jet engine turbine blades and biological implants.

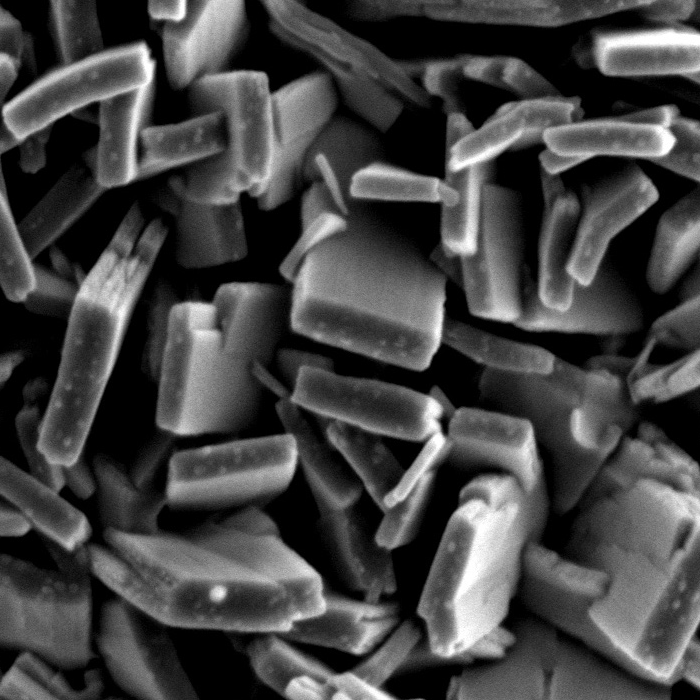

Ceramics are produced from powder precursors that are subsequently heat-treated using a sintering process. The process of sintering is important and influences the final material properties. The final material properties are determined by the bulk material forming or shaping process and by the properties of the particles. The size and shape of the particles are the crucial parameters which must be considered when the material and its properties are designed. Therefore, the particles are a basic parameter affecting the bulk material. The size of the particles together with sintering temperature affects the final grain size and shape, thus this is important from the point of view of the material forming and pores creation. The size and shape of the particle is determined by the powder preparation process. Therefore, the synthesis of the particles is a very important step developing the newmaterial.