When it comes to X-ray analysis we normally think of techniques like XRD (X-Ray Diffraction), XRF (X-Ray Fluorescence and radiography. However, another interesting technique exists that uses x-rays, namely residual stress analysis. A leading light in this field is Scientia Professor Liangchi Zhang at the University of New South Wales, in the School of Mechanical and Manufacturing Engineering.

Residual stresses are those stresses that remain in a material after the cause of the externally applied loads/stresses has been removed. These causes may be from the forming process such as rolling, forging or machining. Depending on the specific application, the residual stress may be advantageous or deleterious.

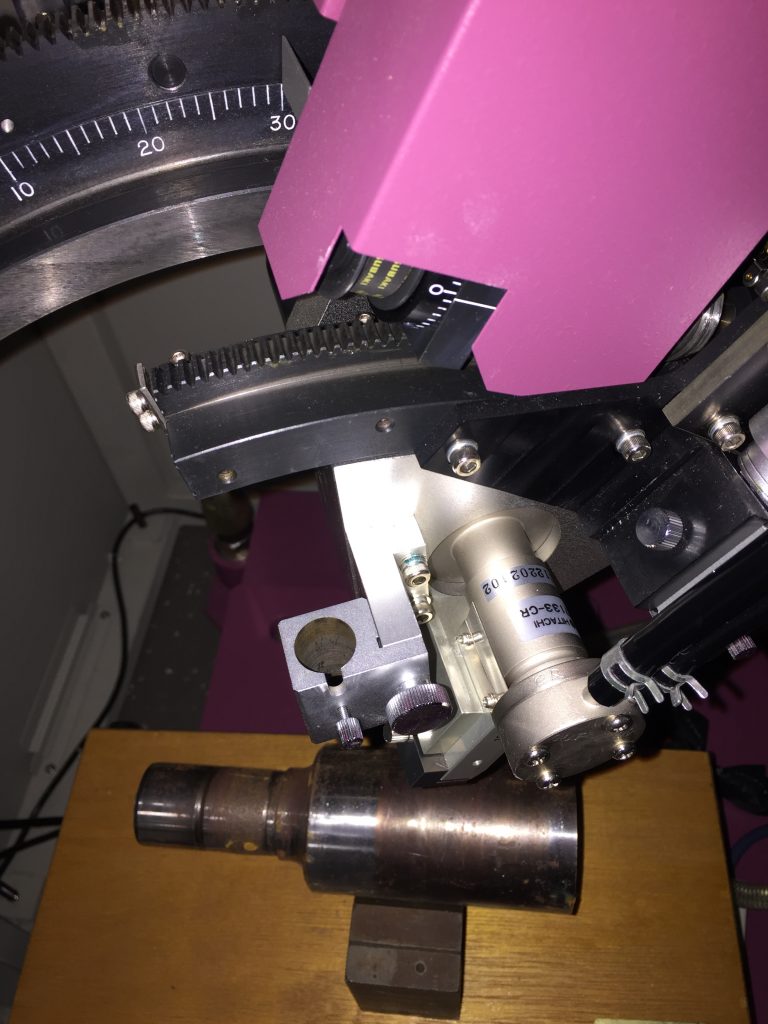

Prior to taking up a posting in Australia, Prof. Zhang’s career had taken him from China, the UK and Japan. During his time in Japan he had worked with a Rigaku Residual Stress Analyser and then acquired a similar instrument, a Rigaku PSPC/MSF rapid stress analyser to conduct research out here.

This system is easily able to cater for small, medium and large samples with a range of different frame sizes. It also produces data very quickly thanks to the Position Sensitive Proportional Counter (PSPC) and the fact that the system can collect data across the entire length of the sample simultaneously. This combination of features makes it the ideal solution for catering for a range of industrial clients who produce such things as gears, rollers for the steel industry, punches, aircraft components, rails and wheels for trains and pistons and cylinders for automotive applications.

When asked about his work, Prof. Zhang commented, “our Rigaku stress analyser is an excellent tool for measuring surface residual stresses. It is ideally suited to metal forming and processing and looking at stress distributions in the resultant components. In most cases, compressive stresses in surface and subsurface regions will increase the service life of a component. By looking at the relationship between processing parameters and the residual stresses induced in the components, we can optimise the processing conditions to produce a component that will ultimately last longer. This can be because we have optimised the fatigue or wear resistance.”

Processes such as grinding can have an effect on residual stresses and impact such things as mould tolerances. In a study with international industrial collaborators, Prof. Zhang published results showing that processes such as surface and plunge grinding, and the resultant heat generated can affect the properties of hardened surface. However, with an understanding of the grinding process, it can be used to generate a hard surface with compressive residual stresses, leading to optimal service performance.